Customers prefer various cutting machines for different materials depending on the sector. The possibilities offered by the technology we have today make designs possible, which allow the completion of various processes depending on the material thickness and dimensions. In order to achieve this, the use of various cutting machines is required. One of these machines is the fiber laser cutting machine.

These are machines that assist in cutting or shaping materials through the use of a laser beam. Besides, they also allow the desired pattern or design to be applied to the material through the marking process. Laser-cutting machines have been used in a number of sectors for many years. In addition, these machines are able to process materials of different hardness and quality according to the relevant configuration. However, customers wonder about many issues such as what the fiber laser cutting machine does and what are the features of these machines. In this article, as Durmazlar, we will answer in detail your concerns about fiber laser cutting machines.

What Does Laser Cutting Refer To?

Generally used for industrial production, laser cutting is a preferred technology for cutting iron, aluminium, stainless, and similar metal materials. Laser cutting is mainly performed by directing the output of a high-power laser through optics.

The laser machine used for cutting materials also includes a motion control system that will follow the CNC or G code of the pattern to be cut into the material. Also, the focused laser beam is directed at the material and then melted, burned, vaporized, or ejected by a jet of auxiliary gas. At the end of the process, customers achieve a high-quality edge surface. Industrial laser cutting machines are preferred for cutting profile and pipe materials as well as flat sheet materials.

What Are the Functions of the Fiber Laser Cutting Machine?

Fiber laser cutting machines have become increasingly popular for businesses in recent years. It can be said that fiber laser cutting machines are an advantageous option due to the wide variety of surfaces that can be cut, the economical maintenance materials, and achieving higher quality products in sensitive processes.

Functioning with the principle of intensive processing, the fiber laser cutting machine’s main criterion is that the output is flawless. The factors affecting the margin of error, which is close to zero, may include the cut surface, detail, and amount of processing.

Areas of Use of Fiber Laser Cutting Machines

Fiber laser cutting machines are used in many areas since they meet expectations in terms of both quality and cost. The general areas of use are as follows:

- Since punches of all shapes and sizes can be prepared through laser cutting, The mold industry is among the areas where laser cutting is used the most.

- Manufacture of machinery and spare parts for machines.

- Fields of architecture and engineering.

- Ship and yacht industry.

- Production of cranes, steel construction, heavy construction machinery, and sub-industry products.

- Manufacture of construction materials, lifts, and sub-industry products.

- Manufacture of laboratory and medical instruments.

- Heating, ventilation, and air conditioning industries.

- Manufacture of exhibition stands, display stands, and shelves.

- Manufacture of electrical and lighting products.

- Production of advertising signs used for visual communication.

Various designs in interior architectural projects. A large number of engravings on furniture, wall decorations, or various objects in the houses. Fiber laser cutting machines offer many advantages. These are as follows:

- Energy-saving

Fiber laser cutting machines save energy. The advanced technology and design it has are ideal for energy saving.

- Reliable

These state-of-the-art laser-cutting machines are designed to offer precise results. In addition, they are durable, reliable, and long-lasting.

- Exclusive

Fiber laser cutting machines in the industrial laser processing market enable precise and serial cutting processes.

Features of Durmazlar Laser Cutting Machines

The types and features of Durmazlar laser cutting machines are as follows:

- Fiber Laser Cutting Power Supply System: BRILASE

Durmazlar designed and developed the first domestic fiber laser power supply system of Türkiye, BRILASE. The superior beam quality they have allows fiber lasers to be the first choice for precision cutting and marking applications.

- HD-TC Laser Pipe and Profile Cutting Machine

Durmazlar HD-TC Laser and Pipe Profile Cutting Machine offer the opportunity of cutting pipe and profile materials with a thickness of 0.8 mm to 10 mm by use of laser cutting power up to 4 kW. The Fully Automatic Loading and Unloading feature requires less operator effort and saves time.

- HD-FO Laser Cutting Machine

Durmazlar HD-FO Laser Cutting Machine stands out with its high-quality materials and industrial designs as well as its production efficiency. The ease of use, low operating costs, fast opening top cover, easy access to the cutting area, compact bridge design, and ease of transportation offered by HD-FO Laser Cutting Machines increase efficiency in all areas.

- HD-FS Laser Cutting Machine

The HD-FS Laser Cutting Machine is designed similarly to the HD-F series using the same components. As Durmazlar, we recommend you use HD-FS Laser Cutting Machine in order to add value to your business by achieving further quality, performance, and efficiency.

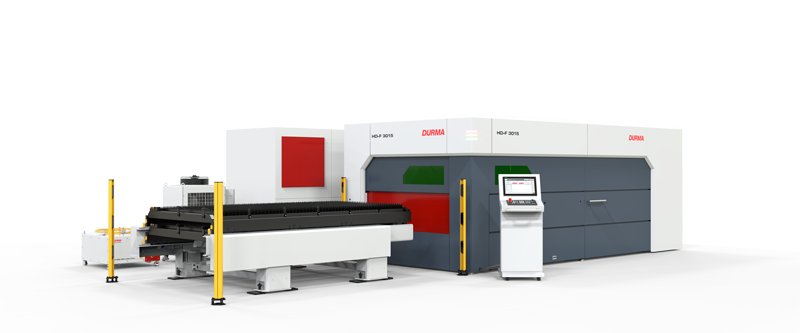

- HD-F Laser Cutting Machine

Durmazlar HD-F Laser Cutting Machine stands out with its fast and precise cutting technology. The servo motor-driven rack and pinion mechanism allows HD-F Laser Cutting Machine to reach high acceleration.

- HD-FL Laser Cutting Machine

Durmazlar HD-FL Laser Cutting Machines are able to reach high accelerations and speeds by use of the linear motor system. They guarantee quality, performance, and effectiveness.

- HD-FA 5 Axis Laser Cutting Machine

HD-FA 5 Axis Laser Cutting Machines are laser cutting machines that can cut three-dimensional parts. Durmazlar HD-FA 5 Axis Laser Cutting Machines are also ideal for automotive and various high precision and 3D complex part production. They also offer several advantages thanks to the cutting system with the feature of “Simple Fixture Usage”.

In this article, as Durmazlar, we have answered in detail your concerns about fiber laser cutting machines. By using Durmazlar machines, you can overcome all difficulties. We mainly aim to combine business processes by producing durable, flexible, and innovative machines. We aim for perfection in all our machines and attach importance to our communication with our customers in order to produce flawless machines. Please visit our website and contact us if you need further information about our products.