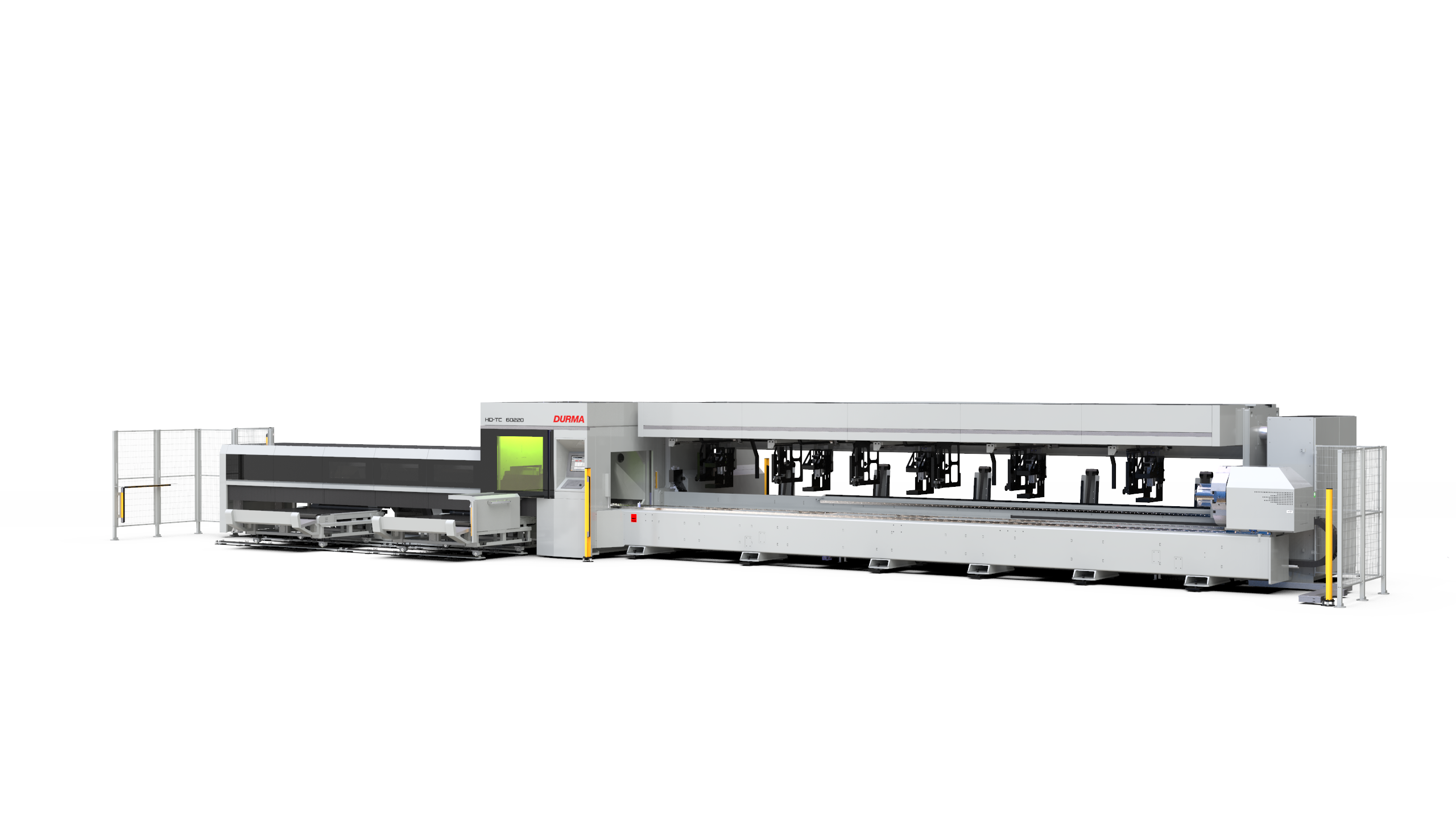

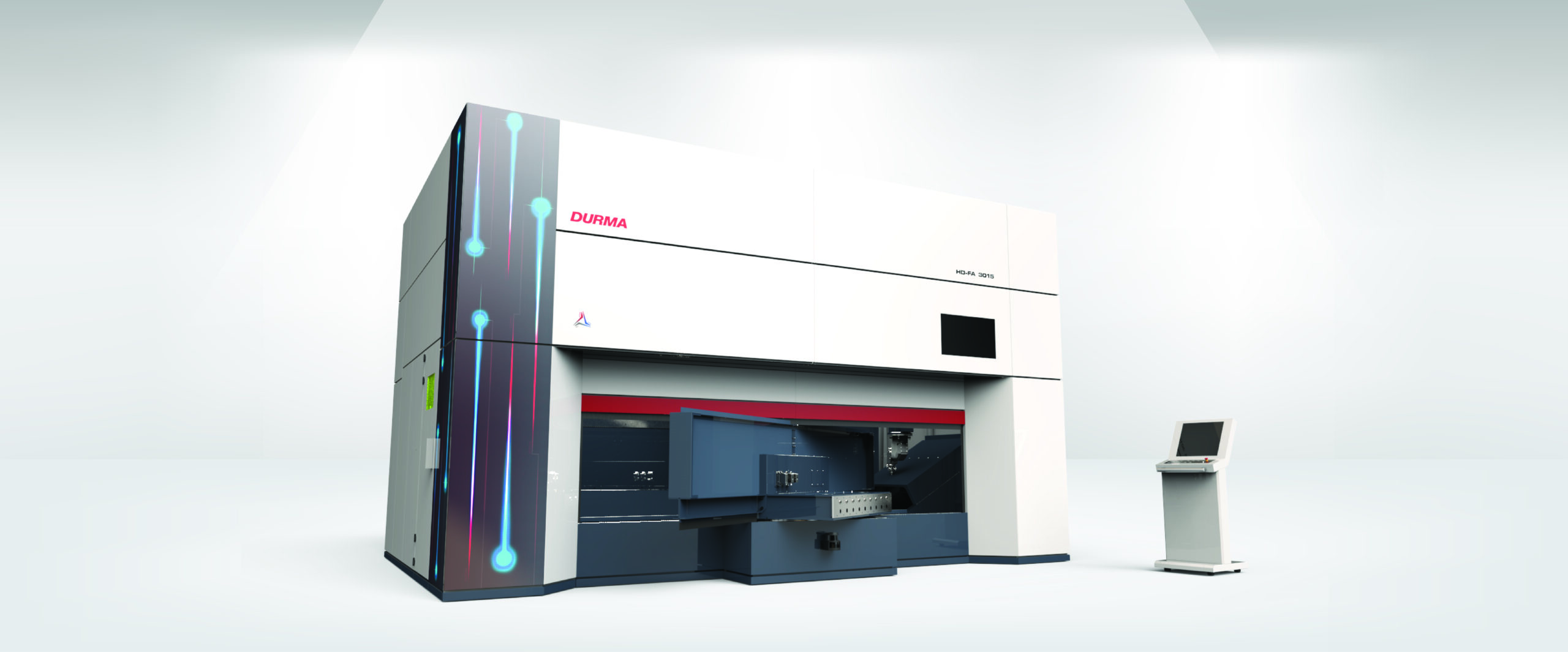

LASER CUTTING MACHINES

Laser cutting machines are machines that are used for precision cutting. A laser cutting machine is used to cut various metals in a precise way. Manufacturing needs vary greatly, and so do the laser cutting machines. The market necessitates every-differing manufacturing requirements. In order to choose the right machine for your needs, the characteristics of the laser cutting machine matters.

Laser cutting machines are used in various industries and have multiple applications. These machines can be used in electronics manufacturing, automotive industry as well as the aerospace industry. They can cut many different types of metals.

Used in mild steel, stainless, aluminum, brass and copper, these machines are an indispensable part of various industries. They deliver clean cuts and precise finishes. The machines can have very different characteristics. Moreover, they can have varying cutting capacities. Sheet metals of differing thickness can be cut. How do laser machines achieve such precise cutting?

How Do Laser Cutting Machines Work?

Briefly explained, laser cutting machines use a focused laser beam to cut. They can cut materials into custom designs, various patterns and the required shapes. Complex parts can be made easily with such machines. In detail, the laser cutting machines work as such:

- The laser light to be used for cutting are created from diodes.

- Fiber lasers use semiconductor diodes as the best light source to pump the active fibers.

- The rays generated in the modules of the laser unit can easily be carried by fiber cable to the cutting head without any power loss.

- In order to cut the material, the laser light is focused by the cutting head.

Laser Cutting Machines: CNC Controlled Systems

Today, many laser cutting machines use a system called computer numerical control. Otherwise known as CNC, these automated systems achieve perfect results. They can control and direct the laser beam to achieve the required shape, size and thickness. Many laser cutting machines are now produced to be computer controlled. This saves manpower, energy and time.

The industrial applications today necessitate a perfect finish. Flawless cuts are needed in order to ensure quality end-products. This is where laser cutting machines are necessary. However, the size and capacity of these laser cutting machines matter. The size and capacity determines its use. Smaller or larger scale manufacturing processes necessitate different types of laser machines.

What Are the Advantages of Laser Cutting Machines?

The main advantages of Durma Laser Cutting Machines are their high precision and accuracy. Secondly, they provide high production speed. Thirdly, they can be applied to cut a wide range of metal materials.

Another of the main advantages of these machines is the variety of its applications. They can be used to cut and shape metal in various thicknesses. Their applications vary from retail product design to industrial equipment.

Moreover, having a Durma Laser Cutting Machine will increase your production capabilities. Thus, it will render your business independent. You won’t need to outsource your precision-cutting needs. This will save your money and time.

Furthermore, a sturdy and durable laser cutting machine will increase your production. These machines ensure uninterrupted operation to meet user manufacturing demands even under challenging industrial conditions and heavy workloads.

What is the Durma Technology?

Durma Laser Cutting Machines are durable. They will be with you for long and productive years. You will save time, energy and manpower due to our cutting-edge technology. Our R&D team continuously works to ensure that your machine is the best the market has to offer. Moreover, you will benefit from Durma after-sales services, we will be with you every step of the way.

A reinforced, close to ground, state-of-the-art frame design, special alloy bridge design with space geometry construction and manufacturing techniques allow Durma Fiber Laser Machines to maintain their precision and durability for numerous years.

The company never compromises on quality, efficiency, and performance of any of its machines and systems it develops. All mechanical and pneumatic systems of fiber lasers are designed by the qualified and experienced engineers at the R & D center, using parametric 3D technology and performing static and mechanism analyses.

Our fiber lasers that are equipped with world-class high-tech products, provide precise solutions for your needs.

How to Choose the Right Laser Cutting Machines for Your Business?

When choosing the right machine for your needs, make sure you know the specifics. What type of metal will you cut? What thickness is the metal you need to cut? How strong does your machine need to be? Answer these questions before you look for a machine. Make sure the machine suits your specific needs. Laser cutting machines are an investment. You will need to minimize your risks. Choosing the right machine for your needs may require research. Don’t forget to ask all your questions. Check out the after-sales services the laser cutting machine provider offers. Compare and contrast your different options. In order to choose the right machine, you will need to do the right research. Be patient and don’t forget to ask many questions before purchasing. Finding the right machine is very important, and you will need to know the specific requirements of your business beforehand.

What to Look for in a Laser Cutting Machine?

Important considerations when shopping for a laser cutting machine:

- Support:How will you find the necessary support when you encounter a problem with your machine? How easy is it to find replacement parts? What are the after-sales services?

- Size:What are your manufacturing needs? Will you need a bigger or a smaller laser machine? How adaptable is the machine to your specific needs?

- Power:What is the laser resonator power of your machine? Do you need a very powerful machine? What are your needs? Usually, more power means you will cut thicker and faster.

- Option: What are the important options you need to increase production efficiency? Specify needs to your provider, and research before purchasing.

Why Should You Choose Durma?

Business, like life, is a journey. With Durma machines, you will overcome all obstacles and surmount all challenges that business presents. We will be with you every step of the way. We know that your growth is our growth, and that your success is our success. As Durma, we manufacture machines that are durable, flexible and innovative. We aim for excellence in all our machines. We build trust with our customers to produce flawless tools. Our cutting-edge technology will get you clear-cut results, fast, with perfection.

Durma, means ‘Keep going’. With Durma you will progress and produce continuously.