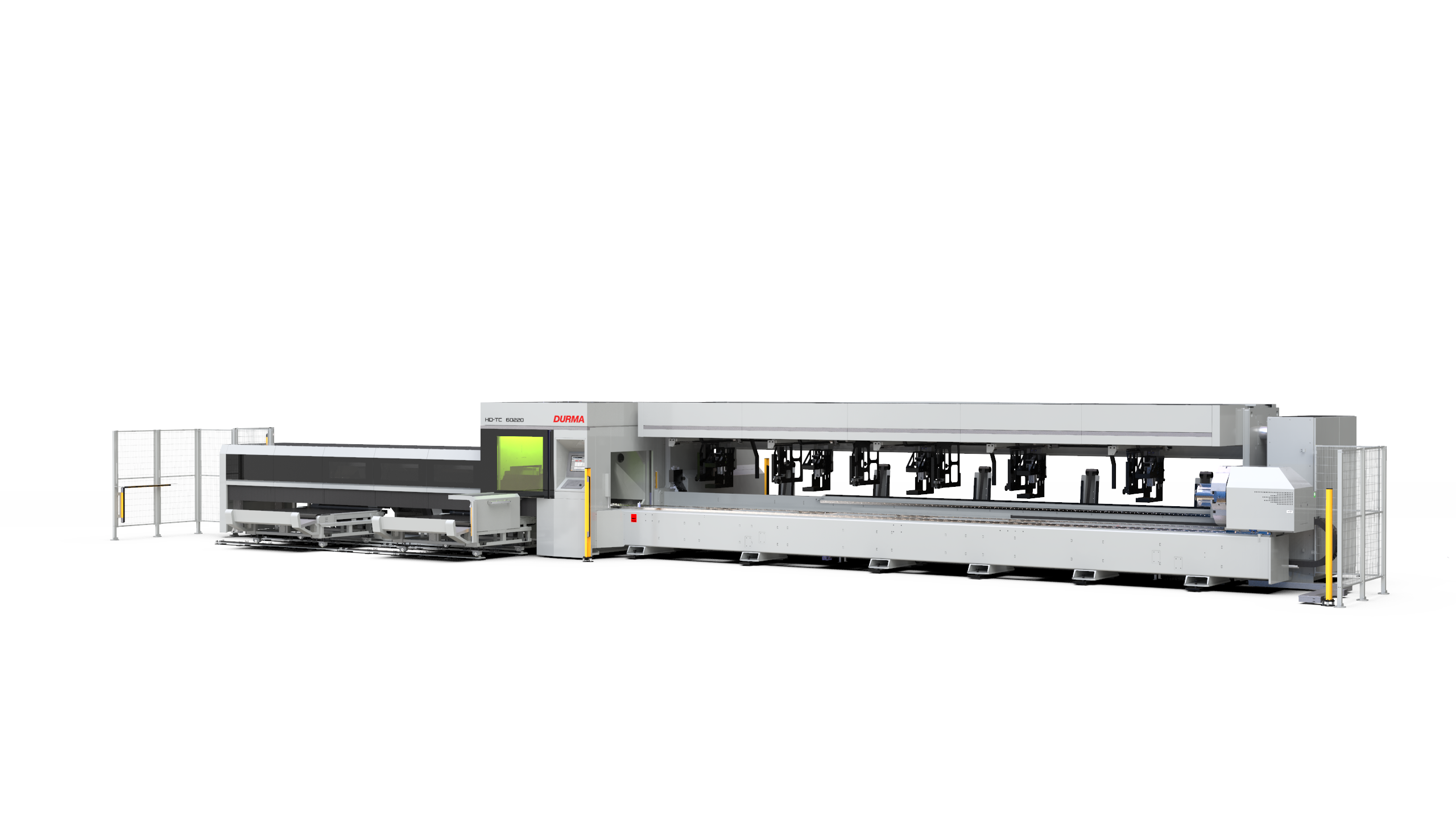

HD-TC Laser Tube Cutting Machine

HD-TC Laser Tube Cutting Machine is used for tube and profile cutting. Laser tube cutting is specifically designed for businesses that care about high quality tube (max Diameter 220 mm) and profile cutting. Using a laser cutting power of up to 3 kW, tube and profile materials of thicknesses from 0.8 mm to 10 mm are cut. Fully automatic Loading and Unloading requires less effort and time save for the operator. The moving axes operate via maintenance-free, dynamic and high-performance AC servo motors. Suction system is used to vacuum the dust generated during laser cutting to the dust collection filter.

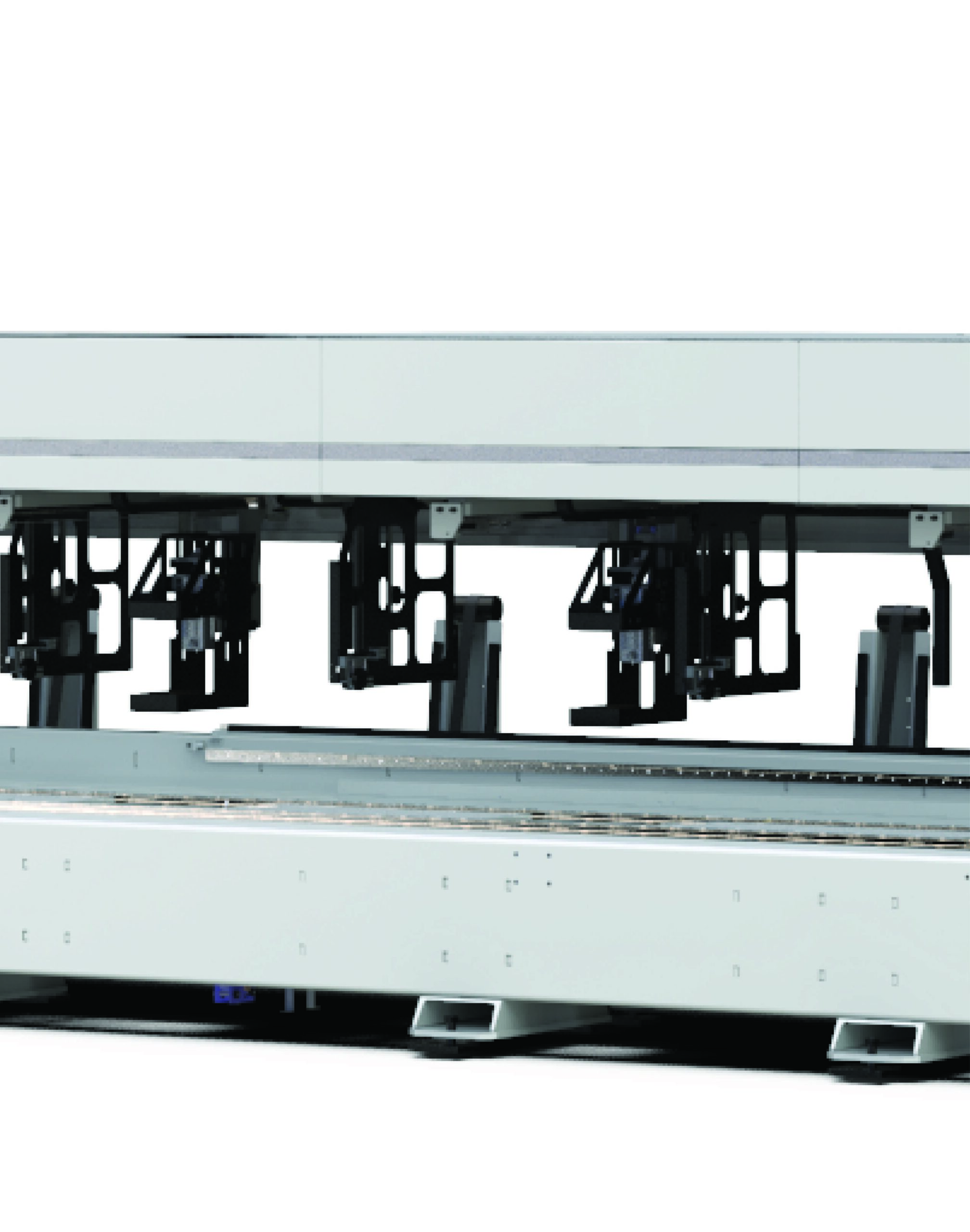

Automatic tube and profile loading system is designed in accordance with the principle of reducing the material preparation time and automatic tube and profile unloading system to collect the cut materials without stopping the machine. Thanks to the compact layout of the machine, all tube and profile loading / cutting / unloading actions are performed with less space and less processing. HD-TC Laser Tube Cutting Machine make differences with speed, high quality components, efficiency and industrial design.

This machine is best suited for business fields which require automatically performing different operations. Operations such as drilling, cutting are done in a short period of time.

Many industries such as automotive, furniture, shelf systems, machine manufacturing, construction, agriculture machinery and steel construction can use HD-TC Laser Tube Cutting Machines. Utilization of tubes and profiles are widespread among many business fields. These are energy conveying lines, telecommunication and agriculture machinery. Moreover, steel construction, automotive, furniture and machine manufacturing. Processes such as cutting different geometrical shapes can be easily done. Most of the applications aim for high sensitivity levels in such processes. It is apparent that implementing laser technology in tube profile cutting will create an opportunity for aesthetical and flexible designs. Moreover HD-TC Laser Tube Cutting Machine offers high speed in production, as well as sheet cutting.

What are the Advantages of the Durma HD-TC Laser Tube Cutting Machine?

- User Friendly

Durma HD-TC Laser Tube Cutting Machine is specifically designed to be user friendly. Its automated work process will save you time. Its ergonomic design makes it easy-to-use. - Energy Efficient

Durma HD-TC Laser Tube Cutting Machine is designed to be energy efficient. Its advanced technology and design are optimal to save space and energy. We as Durma know that you need an efficient and easy-to-use machine. It is a machine that is fast, ergonomic and easy to operate. If this suits your needs, then this machine is the right choice for you. The advanced Durma technology is specifically designed to ensure that your machine has low running costs. Your machine will make you save on energy bills as well as time and manpower.

- Reliable

The state of the art Durma technology is manufactured to provide precise results. Durma HD-TC Laser Tube Cutting Machine is a durable, reliable machine. It will be with you for long years. The precise technology will ensure reliable results, every time.

Why Should You Choose Durma?

Business, like life, is a journey. With Durma machines, you will overcome all obstacles and surmount all challenges that business presents. We will be with you every step of the way. We know that your growth is our growth, and that your success is our success. As Durma, we manufacture machines that are durable, flexible and innovative. We aim for excellence in all our machines. We build trust with our customers to produce flawless tools. Our cutting-edge technology will get you clear-cut results, fast, with perfection.

Durma, means ‘Keep going’. With Durma you will progress and produce continuously.